Wire cup brushes are versatile tools commonly used in various industries and DIY projects for rust and paint removal, surface preparation, and cleaning. Selecting the right wire cup brush for your project is crucial to ensure efficiency, safety, and the best results.

Wire cup brushes consist of wire bristles securely mounted on a central hub, forming a cup shape. These brushes are designed to attach to angle grinders, drills, or other power tools to remove rust, paint, and corrosion and prepare surfaces for welding or painting.

Types of Wire Cup Brushes

There are three primary types of wire cup brushes:

Crimped Wire Cup Brushes

Crimped wire cup brushes are suitable for lighter-duty applications such as cleaning and polishing. They provide flexibility and are less aggressive than other types, making them ideal for tasks that require a gentle touch.

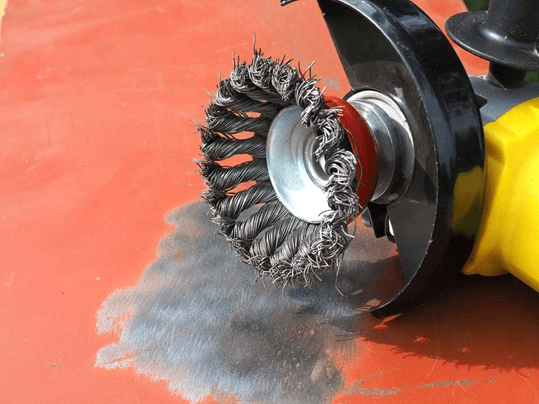

Knot Wire Cup Brushes

Knot wire cup brushes are more aggressive and suitable for heavy-duty applications like weld cleaning, deburring, and surface preparation. Their twisted knot design ensures maximum cutting action.

Twisted Wire Cup Brushes

Twisted wire cup brushes offer a balance between crimped and knot wire brushes. They are versatile and can handle various tasks, including rust and paint removal.

Choosing the Right Wire Material

Wire cup brushes come in different materials, including steel, stainless steel, and brass. The choice of wire material depends on the specific job requirements. Steel is ideal for heavy-duty tasks, while stainless steel is corrosion-resistant and suitable for wet environments. Brass is non-sparking and often used in sensitive areas.

Selecting the Appropriate Wire Gauge

The wire gauge determines the thickness of the wire bristles. Thicker gauges are more durable and suitable for demanding applications, while thinner gauges are better for finer work. Consider the materials you’ll be working with when selecting the wire gauge.

Brush Diameter Matters

The diameter of the wire cup brush affects its coverage area and aggressiveness. Larger brushes cover more surface area but may be challenging to control. Smaller brushes offer precision but require more time for larger projects.

Arbor Size and Compatibility

Ensure your wire cup brush matches your power tool’s arbour size. Using the right arbour size can lead to safety hazards and efficient operation.

RPM and Speed Requirements

Refer to the manufacturer’s recommendations for your wire cup brush’s recommended RPM (rotations per minute) and speed settings. Operating at the correct speed ensures both safety and optimal performance.

Safety Precautions and Personal Protective Equipment (PPE)

Always wear appropriate PPE, including safety glasses, gloves, and a dust mask when using wire cup brushes. Ensure your workspace is well-ventilated and free of flammable materials.

Proper Techniques for Wire Cup Brush Usage

Use a light and even pressure when operating the wire cup brush. Avoid excessive force, which can cause the brush to wear out quickly and damage the workpiece. Move the brush in a consistent and controlled manner for the best results.

Cleaning and Maintenance

After use, clean your wire cup brush thoroughly to remove any debris and prevent premature wear. Regularly inspect the brush for signs of damage or wear and replace it as needed.

When to Replace Your Wire Cup Brush

Suppose you notice a significant reduction in performance, such as decreased material removal or excessive wear of the wire bristles. In that case, it’s time to replace your wire cup brush. Using a worn-out brush can lead to inefficient work and safety risks.

Benefits of Using the Right Wire Cup Brush

Choosing the appropriate wire cup brush for your project offers several advantages, including improved efficiency, better surface finish, and reduced project completion times. It also helps prevent damage to the workpiece and minimizes the risk of accidents.

Common Mistakes to Avoid

- Using the wrong type of wire cup brush for the job.

- Neglecting safety precautions and PPE.

- Overloading the brush with excessive pressure.

- Failing to clean and maintain the brush regularly.

Expert Tips for Wire Cup Brush Selection

- Consult with experts or professionals in your industry for advice on the best wire cup brush for your specific application.

- Invest in high-quality brushes from reputable manufacturers to ensure performance and safety.

- Practice on scrap material before starting your project to get a feel for the brush’s performance.

Conclusion

Choosing the right industrial brushes is essential for the success of your project. Consider brush type, wire material, gauge, diameter, and safety precautions. By making informed choices, you can achieve better results, enhance efficiency, and ensure safety during every project.